Unlock the Editor’s Digest for free

Roula Khalaf, Editor of the FT, selects her favourite stories in this weekly newsletter.

Taiwan Semiconductor Manufacturing Company has cut its profitability target despite roaring demand for artificial intelligence chips, as the cost burden of diversifying global chip supply chains starts to bite.

The world’s largest chip manufacturer said gross margin was expected to drop by a percentage point in the current quarter from 59 per cent in the three months to December 31, due to higher costs at its new fabrication plants, or fabs, in the US and Japan.

The contract chipmaker has committed to building three fabs in Arizona, at least two in Kumamoto and one in Dresden, Germany, in response to pressure from customers and foreign governments to rebuild some chip manufacturing capacity in those countries following decades of outsourcing to Asia. More than 90 per cent of the world’s most advanced chips are currently built in TSMC’s fabs in Taiwan.

The margin dilution effect would “become more pronounced throughout the year as Kumamoto and Arizona ramp up” and would reach two to three percentage points a year over the next five years, said Wendell Huang, chief financial officer.

The margin pressure comes even as TSMC expects continued strong growth in demand for the AI chips it manufactures for Nvidia and other big customers. The company forecast its overall revenue would increase by close to 25 per cent this year and close to 20 per cent annually over the next five years, driven by 45 per cent annual compound growth in AI chip revenue.

In a reflection of that bullish outlook, TSMC said it would increase capital spending this year to between $38bn and $40bn, a more than 30 per cent increase after stagnating for three years.

When the last semiconductor cycle peaked, TSMC’s gross profit margin hit 62.2 per cent in the final quarter of 2022. But the company suggested that remained an exception. “If the capacity utilisation rate is very high, it is not impossible for us to reach” a level above 60 per cent, said Huang.

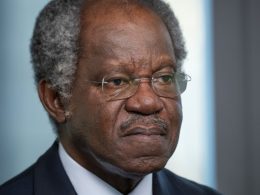

CC Wei, chief executive, said TSMC was working on a “new methodology that will give Arizona some benefit to minimise the cost gap” against fabs in Taiwan. It would include the use of AI to streamline its transfer of new manufacturing processes from Taiwan and find a “more intelligent ramp-up process”, Wei said.

Other efforts to narrow the cost gap include building a more complete supply chain locally. But “we need the US government’s help for that”, he added.

TSMC beat its own guidance and analysts’ expectations with a 57 per cent year-on-year increase in net profit to NT$374.68bn (US$11.4bn) for the December quarter — the fastest growth in two years — and a 38.8 per cent increase in revenue to NT$868.46bn.

The company said the impact on its operations from Washington’s latest export controls this week, which will restrict the supply of AI chips to all countries but a small group of US allies and partners, would be “minimal”.

“We have communicated with the US government,” said Wei. “We understand from that communication that what they care about most is AI and that they view automotive, consumer electronics and other applications as normal business.”

It would therefore be “easier to receive approval”, he added, to ship chips for those other applications.

Source link